from Aton Resources, Inc. (CVE:AAN)

Aton Reports New Results From Metallurgical Testing on Abu Marawat Oxide, Transition and Sulphide Mineralisation

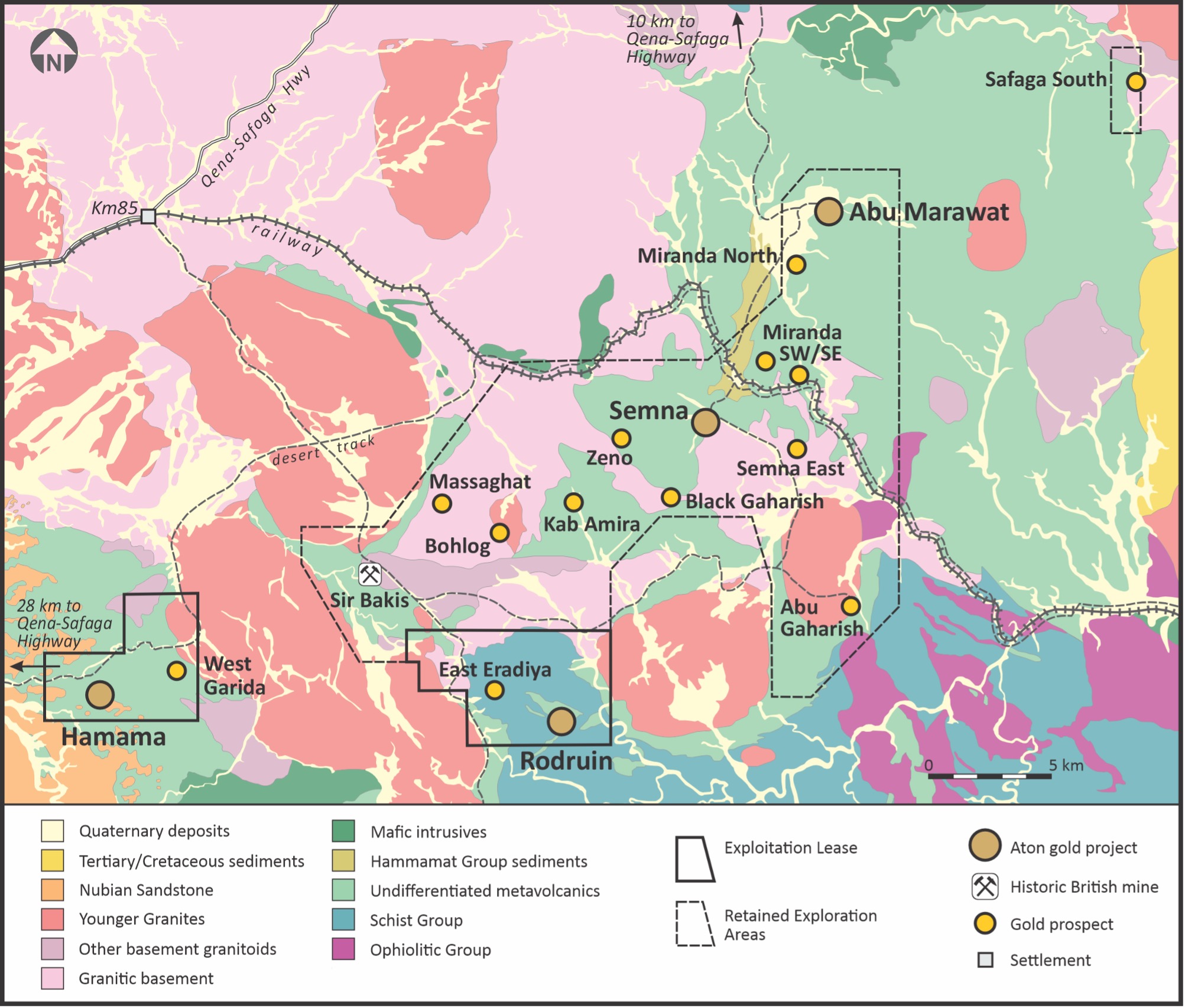

VANCOUVER, BC / ACCESS Newswire / January 5, 2026 / Aton Mining Inc. (AAN:TSX-V) ("Aton" or the "Company") is pleased to update investors on the results of metallurgical testwork from its Abu Marawat deposit ("Abu Marawat"). Abu Marawat is located within the Company's 100% owned Abu Marawat Concession ("the Concession"), in the Eastern Desert of Egypt.

Highlights:

Nine composite samples representing the main mineralisation types at Abu Marawat underwent preliminary metallurgical testwork investigating several different process options. The composite samples were prepared from selected diamond drill core intervals and RC chips;

The samples exhibit medium to hard grinding characteristics, with Bond Rod and Ball Mill Work Indices ranging from 12.8-17.1 kWh/t. Abrasion Indices indicate slightly to moderately abrasive behaviour. Sulphide composite AM-MET03 exhibits hard crushing characteristics, while oxide samples are classified as medium;

Whole ore cyanide leaching resulted in gold extractions ranging from 69.8% to 90.7%, and silver extractions between 48.3% and 88.4%. Cyanide consumption (3.2-9.2 kg/t) and lime consumption (0.6-12.0 kg/t) varied by ore type. Sulphide and transitional samples generally achieved the highest extraction efficiencies. Overall, the testwork demonstrated that gold is largely amenable to cyanide leaching, with silver recovery being more variable;

Copper rougher flotation achieved 67-92% copper recovery with concentrate grades of 4-19% Cu, depending on mineralisation type. Gold recovery in copper concentrates ranged from 40-75%, and silver from 56-80%. Several samples (e.g. Fin Vein transitional and CVZ oxide) produced high grade copper concentrates with significant precious metal enrichment;

Cleaner stages produced high grade copper concentrates (up to 45% Cu), but at the cost of significant recovery losses (often 10-40% Cu recovery in the cleaners). While copper and gold recoveries decreased in cleaner circuits, silver grades remained notably high. Silver consistently reported strongly to copper concentrates, frequently achieving 2-6 kg/t Ag in the cleaner products;

Zinc depression proved challenging when testing the transitional ore types, especially for the CVZ transitional composite, with zinc misreporting to copper concentrates even at elevated dosages of zinc depressants. In contrast, the Fin Vein transitional composite responded better, with improved zinc depression;

Saleable copper and zinc concentrates were achieved during testing of the CVZ sulphide composite sample. The copper circuit achieved a concentrate grade of 23.7% Cu at 48.3% recovery, whilst the zinc circuit achieved a concentrate grade of 60.4% Zn at 72.3% recovery;

Leaching of flotation tailings provided substantial incremental recovery, adding a further 60-86% gold extraction and 37-64% silver extraction from the final cleaner tailings;

SART testing exhibited a high degree of sulphide precipitation for dissolved copper, zinc, and silver (typically >97% precipitated from solution in 15 minutes), enabling significant cyanide regeneration. Gold extraction was limited (~62%) due to reduction to elemental gold and, possibly co-precipitation and entrainment.

Overall, metallurgical testing of the Abu Marawat composite samples demonstrated that:

The mineralisation responds strongly to conventional cyanide leaching, especially for gold;

High value copper concentrates containing significant silver credits are achievable, albeit with some recovery losses;

Zinc depression proved a challenge, especially in CVZ and Fin Vein transitional mineralisation types;

Zinc cleaner flotation can produce marketable high-grade concentrates with moderate recovery;

A flotation + leach flowsheet offers improved overall metal extraction; and

SART can be highly effective for cyanide recovery and base metal removal at Abu Marawat.

"These preliminary metallurgical testwork results from the Abu Marawat polymetallic mineralisation are most encouraging, and indicate that the oxide mineralisation types can be processed economically using a fairly conventional process route for copper ores with high cyanide soluble copper content, that is by producing a saleable copper concentrate with precious metal credits, a saleable sulphide concentrate from SART, and doré from a Merrill-Crowe circuit" said Tonno Vahk, CEO. "Transitional ores from the CVZ and Fin Vein can be processed by conventional flotation to produce a saleable zinc concentrate with copper, gold and silver credits, which also could potentially be sold as a precious metals concentrate. The CVZ and Fin Vein sulphide mineralisation can be processed by sequential flotation to produce saleable copper and zinc concentrates, containing very respectable gold and silver metal credits. The latest phase of drilling has also been completed at Abu Marawat and our consultants are about to commence work on updating the Abu Marawat mineral resource estimate. This preliminary metallurgical testwork programme has identified potential processing routes for the production of gold, silver, copper and zinc from Abu Marawat, allowing the Company to push ahead towards its goal of incorporating both the Abu Marawat and Semna deposits, where drilling is ongoing, into the Abu Marawat exploitation lease."

Abu Marawat gold-silver-copper-zinc project

The Abu Marawat gold-silver-copper-zinc deposit is located approximately 35km northeast of the Hamama West deposit and 10km north-northeast of the Semna gold mine project, and is accessed via a well maintained desert track from the Qena-Safaga highway, approximately 25km to the north (Figure 1). On March 1, 2012 Aton Resources, when formerly named Alexander Nubia International Inc, announced a maiden Inferred Mineral Resource at Abu Marawat, prepared by Roscoe Postle Associates Inc., in compliance with the requirements set out in Canada's National Instrument 43â101. The resource was subsequently restated in an updated Technical Report without amendment (see news release dated January 24, 2017), and which is available online at Aton's website at https://atonresources.com/investors/reports-and-presentations. This Inferred Mineral Resource was based on 98 diamond drill holes totalling 19,573 metres. 19 of these holes were drilled by a former property owner, Minex Minerals Egypt, a wholly owned subsidiary of Greenwich Resources Plc during the late 1980's, and the remainder were drilled by Aton in 2011. The Inferred Mineral Resource comprises 2.9 million tonnes at an average grade of 1.75 g/t Au, 29.3 g/t Ag, 0.77% Cu and 1.15% Zn, containing 162 thousand ounces of gold, 2.7 million ounces of silver, 49 million lbs of copper, and 73 million lbs of zinc, and was based on net smelter return ("NSR") cutâoff grades.

During 2025 Aton completed a 113 hole diamond drilling programme (holes AMD-101 to AMD-213), for a total of 9,643 metres drilled (see news release dated October 2, 2025), focused primarily on the more gold and silver-rich parts of the CVZ and the Fin Vein, of which several holes were designed specifically for the collection of metallurgical testwork samples. In November 2025, Aton also completed a 71 hole reverse circulation percussion ("RC") drilling programme (holes AMP-214 to AMP-284), for a total of 6,647 metres drilled. The final results are not yet available for this RC programme, but are expected to be reported shortly.

The polymetallic mineralisation at Abu Marawat is interpreted as being mesothermal in origin, and occurs in a series of discrete and roughly parallel N-S to NNW-SSE trending veins and structures, of which the Fin Vein and the Central Vein zone ("CVZ") are the most significant, hosted within a sequence of intensely hydrothermally altered, felsic metavolcanic rocks. The Fin Vein and the CVZ are about 50-100m apart and have been traced for at least 800m in surface outcrop and drill holes. The bulk of the Inferred Mineral Resource at the Abu Marawat deposit encompasses parts of the CVZ and the Fin Vein, but there are also other subparallel mineralised veins to the east and to the west of these structures, such as the J Vein, the JVZ structure.

Figure 1: Geology plan of the Abu Marawat Concession, showing the location of the Abu Marawat deposit

Metallurgical testwork programme

Nine composite samples were prepared from the Abu Marawat deposit for metallurgical testing (AM-MET01 to AM-MET09), representing the oxide, transitional and sulphide mineralisation types associated with the CVZ, the Fin Vein and the JVZ structure.

The preliminary testwork programme was designed to evaluate several different options for processing copper ores with high cyanide soluble copper content, and surface mineral oxidation. Typically, when copper oxide-bearing gold mineralisation with high cyanide soluble copper content is processed via conventional CIL, this results in high cyanide consumption. The programme specifically focused on evaluating conventional cyanide leaching versus flotation-CIL for the oxide mineralisation. A limited programme of sulphidisation, acidification, re-cycling and thickening ("SART") testing was undertaken to determine the potential for recovering metals including copper, gold, silver and zinc from a gold cyanidation leach solution generated from a blend of oxide mineralisation from the CVZ.

The transitional and sulphide ores were also tested by conventional flotation to determine whether separate saleable copper and zinc concentrates could be produced.

Nine composite samples for metallurgical testwork were prepared, representing the main mineralisation types present at Abu Marawat. The samples were selected from diamond drill core (both HQ and PQ size, samples AM-MET01 to AM-MET08), and RC drill chips (sample AM-MET09). Details of the samples are provided in Table 1.

Sample ID | Sample type | Testwork planned | Material type | Aton estimated grades | |||

Au (g/t) | Ag (g/t) | Cu (%) | Zn (%) | ||||

AM-MET01 | Fin Vein oxide | comminution | PQ whole core | - | - | - | - |

AM-MET02 | CVZ oxide | comminution | PQ whole core | - | - | - | - |

AM-MET03 | CVZ transitional | comminution / flotation | PQ whole core | - | - | - | - |

AM-MET04 | Fin Vein transitional | leach test / flotation | PQ/HQ half core | 5.00 | 176 | 0.31 | 3.91 |

AM-MET05 | Fin Vein oxide | leach test | PQ/HQ half core | 4.78 | 103 | 0.44 | 3.80 |

AM-MET06 | CVZ oxide | leach test | HQ half core | 3.05 | 35.6 | 1.21 | 0.39 |

AM-MET07 | CVZ oxide | leach test | HQ half core | 2.64 | 34.3 | 0.79 | 1.23 |

AM-MET08 | JVZ oxide | leach test | PQ/HQ half core | 3.31 | 36.3 | 0.25 | 0.62 |

AM-MET09 | CVZ sulphide | leach test / flotation | RC chips | 4.37 | 99 | 0.38 | 4.36 |

Table 1: Abu Marawat metallurgical sample details

Aton dispatched the nine composite samples from Egypt, totalling 350 kg in weight, to SLR Consulting ("SLR"), for metallurgical testing at their laboratory, located in Cornwall, UK. The samples were delivered in two batches, with the initial set of eight diamond drill core samples weighing 330 kg dispatched to SLR during July 2025 (samples AM-MET01 to AM-MET08). Sample AM-MET09, weighing 19.5 kg, was dispatched from Egypt and received by SLR in October 2025. The testwork was conducted between July and November 2025.

A summary of the samples received and the testwork carried out on each sample is shown in Table 2 below.

Date received | Sample ID | Testwork completed | Mass (kg) |

15/7/2025 | AM-MET01 | comminution / whole ore leach | 68.3 |

AM-MET02 | comminution / whole ore leach | 70.1 | |

AM-MET03 | comminution / whole ore leach / flotation | 90.2 | |

AM-MET04 | whole ore leach / flotation | 16.4 | |

AM-MET05 | whole ore leach / flotation / leach | 22.2 | |

AM-MET06 | whole ore leach / flotation / leach | 20.7 | |

AM-MET07 | whole ore leach / flotation / leach | 21.1 | |

AM-MET08 | whole ore leach / flotation / leach | 21.5 | |

7/10/2025 | AM-MET09 | whole ore leach / flotation | 19.5 |

Total | 350.0 | ||

Table 2: Sample receipt summary

Head assays

A representative sub-sample of composite samples AM-MET01 to AM-MET08, and latterly AM-MET09, were extracted, pulverised to <75µm and submitted for chemical analysis for the following elements; Au, Ag, total Cu ("Cu (TOT)"), soluble Cu ("Cu (CN SOL)"), Pb, Zn, As, total S ("S(TOT)"), Hg and Te. The results of the head assays are provided in Table 3.

The Au head assays measured by screen fire assay (Table 3) show reasonably good correlation with the estimated grade of the composited drill core samples (Table 1). Ag, Cu, Pb and Zn head assays also showed reasonable correlation with the estimated grades of the composite samples. The reasonably good correlation in assay results indicates that the composite samples prepared for metallurgical testwork are representative of the drill core intervals sampled. Samples AM-MET01 to AM-MET03 consisted of whole core and were selected on the basis of the visual identification of mineralisation, however, no grades could be estimated for these samples prior to their selection, collection and dispatch from site.

Sample ID | Au (g/t) | Ag (g/t) | CuTOT (%) | CuCN-SOL (%) | Pb (%) | Zn (%) | STOT (%) | |

AM-MET011 | Fin Vein oxide | 11.5 | 184 | 0.63 | - | - | 5.80 | - |

AM-MET012 | Fin Vein oxide | 11.7 | 212 | 0.63 | 0.40 | - | 5.71 | 0.04 |

AM-MET021 | CVZ oxide | 15.1 | 104 | 1.82 | - | - | 0.83 | - |

AM-MET022 | CVZ oxide | 15.1 | 122 | 1.79 | 1.53 | - | 0.92 | 0.07 |

AM-MET03 | CVZ transitional | 1.6 | 42.0 | 0.38 | 0.13 | 0.00 | 1.56 | 2.51 |

AM-MET04 | Fin Vein transitional | 3.9 | 152 | 0.35 | 0.07 | 0.11 | 3.99 | 3.05 |

AM-MET05 | Fin Vein oxide | 5.6 | 96.9 | 0.46 | 0.29 | 0.18 | 4.20 | |